|

Xi'an Hongtu bearings Co.,Ltd.

|

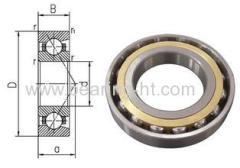

thin section angular contact ball bearing 7208C

| Payment Terms: | T/T,WU |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Angular Contact Ball Bearings:

thin section angular contact ball bearing

1.High quality

2.ISO9001:2000

3.Quick delivery.

4.long service life

thin section angular contact ball bearing 7208C specification:

Angular contact ball bearings features :

1) Load capacities are higher than deep groove ball bearings of same dimensions

2) Used for bearing radial-axial combined loads or pure thrust loads

3) Low operating friction and high limiting speed

Specification:

1. Chrome steel GCR15, SAE52100, 100Cr6

2. ABEC-1, ABEC-3, ABEC-5

3. 7000, 7200, 7300, 7400, 3200, 3300, 4200, 4300, QJ series

Product description:

Angular contact ball bearings are able to support radial lode and axial lode. As single row angular contact ball bearings can only support axial lode in single direction, matched bearing mounting is often adopted to them. As matched pairs of bearing, preload for them is more convenient. Retainers are made of brass, synthetic resins or other subject to individual bearing features and application conditions.

Features:

1) Load capacities are higher than deep groove ball bearings of same dimensions

2) Used for bearing radial-axial combined loads or pure thrust loads

3) Low operating friction and high limiting speed

An angular contact ball bearing uses axially asymmetric races. An axial load passes in a straight line through the bearing, whereas a radial load takes an oblique path that tends to want to separate the races axially. So the angle of contact on the inner race is the same as that on the outer race. Angular contact bearings better support "combined loads" (loading in both the radial and axial directions) and the contact angle of the bearing should be matched to the relative proportions of each. The larger the contact angle (typically in the range 10 to 45 degrees), the higher the axial load supported, but the lower the radial load. In high speed applications, such as turbines, jet engines, and dentistry equipment, the centrifugal forces generated by the balls changes the contact angle at the inner and outer race.

Angular contact ball bearings can bear not only axail but also radial loading capacity.Though only bearing unilateral axial loading capacity, they can be used together with the bearings bears opposite axial loading capacity. Angular contact ball bearings, with a limit ability to self-aligning, can not be dismantled.

contact ball bearing details

Angular contact ball bearings are able to support radial load and axial load. As single row angular contact ball bearings can only support axial load in single direction, matched bearing mounting is often adopted to them. As matched pair of bearings, preload for them is more convenient. Retainer are made of brass, synthetic resins or others subject to individual bearing features and application conditions.

1).Main structure

A. single-row angular contac ball bearing

single-row angular contac ball bearing have separable and non-separable designs,such as S7000 series and SN7000 series.

B. double-row angular contact ball bearing.

C. paired and match angular contact ball bearing

Angular contact ball bearing type:

Single row angular contact ball bearing: only carry a direction of the axial load, when in bear radial load, can cause additional axial force must be applied to the corresponding reverse load, therefore, the bearings are generally used in pairs.

Double row angular contact ball bearing: At the same time can bear radial and axial load joint load, limit shaft on both sides of the axial displacement.

Angular contact ball bearing main technical indicators:

(1) Bearing precision index: More than GB / 307.1-94 P4 level accuracy

(2) High-speed performance index: 1.3~1.8x 106 /min

(3)Service life:more than 1500h

Feature:

1) Load capacities are higher than deep groove ball bearings of same dimensions

2) Used for bearing radial-axial combined loads or pure thrust loads

3) Low operating friction and high limiting speed

Type:

1). Single row angular contact ball bearings

2). Double row angular contact ball bearings

3). Four-point contact ball bearings

Mounting

/DB: Mount in duplex, back to back

/DF: Mount in duplex, face to face

/DT: Mount in duplex, tandem

Angular Contact Ball Bearings (7000C 7200C 7300C C and AC Series)

1) Good performance

2) Low noise, long service life

3) Competitive price

4) Prompt delivery

Introduction

Angular contact ball bearing can bear radial load and axial load,and can work in high revolving speed.

Application feilds

Machine tool spindle, high frequency motor, gas turbine, centrifugal separator, small car front wheel, filling machine, differential pinion shaft, booster pump, drilling platform, food machinery, dividing head, low noise type cooling tower, electrical equipment, coating equipment, machine tool trough plate, arc welding machine.

| Model Number | 7208C |

| Bore Size | 40 mm |

| Outside Diameter | 80 mm |

| Material | Chrome steel, Carbon steel |

| Bearing Type | Angular Contact Ball Bearing |

| Bearing Cage | Steel Cage ,Brass Cage,Nylon Cage |

| Precision Rating | P0 P6 P5 P4 P2 |

| Place of Origin | Shaanxi,China |

| Sample | Free |

| Certification | ISO9001:2000 |

| Angular Contact Ball Bearing | |||||

| Model | Old model | Dimesion(mm) | Weight | ||

| d | D | T | |||

| 7000AC | 46100 | 10 | 26 | 8 | 0.02 |

| 7001AC | 46101 | 12 | 28 | 8 | 0.02 |

| 7002AC | 46102 | 15 | 32 | 8 | 0.03 |

| 7003AC | 46103 | 17 | 35 | 10 | 0.03 |

| 7004AC | 46104 | 20 | 42 | 10 | 0.07 |

| 7005AC | 46105 | 25 | 47 | 12 | 0.08 |

| 7006AC | 46106 | 30 | 55 | 13 | 0.12 |

| 7007AC | 46107 | 35 | 62 | 14 | 0.14 |

| 7008AC | 46108 | 40 | 68 | 15 | 0.21 |

| 7009AC | 46109 | 45 | 75 | 16 | 0.24 |

| 7010AC | 46110 | 50 | 80 | 16 | 0.26 |

| 7011AC | 46111 | 55 | 90 | 18 | 0.38 |

| 7012AC | 46112 | 60 | 95 | 18 | 0.45 |

| 7013AC | 46113 | 65 | 100 | 18 | 0.5 |

| 7014AC | 46114 | 70 | 110 | 20 | 0.59 |

| 7015AC | 46115 | 75 | 115 | 20 | 0.75 |

| 7016AC | 46116 | 80 | 125 | 22 | 0.9 |

| 7016ACM | 46116H | 80 | 125 | 22 | 0.9 |

| 7017AC | 46117 | 85 | 130 | 22 | 0.95 |

| 7017ACM | 46117H | 85 | 130 | 22 | 0.95 |

| 7018AC | 46118 | 90 | 140 | 24 | 0.96 |

| 7018ACM | 46118H | 90 | 140 | 24 | 0.96 |

| 7019AC | 46119 | 95 | 145 | 24 | 1.2 |

| 7019ACM | 46119H | 95 | 145 | 24 | 1.2 |

| 7020AC | 46120 | 100 | 150 | 24 | 1.25 |

| 7020ACM | 46120H | 100 | 150 | 24 | 1.25 |

| 7021ACM | 46121H | 105 | 160 | 26 | 1.61 |

| 7022ACM | 46122H | 110 | 170 | 28 | 2.44 |

| 7024ACM | 46124H | 120 | 180 | 28 | 2.62 |

| 7026ACM | 46126H | 130 | 200 | 33 | 3.912 |

| 7028ACM | 46128H | 140 | 210 | 33 | 4.2 |

| 7030ACM | 46130H | 150 | 225 | 35 | 5 |

| 7032ACM | 46132H | 160 | 240 | 38 | 5.02 |

| 7034ACM | 46134H | 170 | 260 | 42 | 8.3 |

| 7038ACM | 46138H | 190 | 290 | 46 | 11.2 |

| 7040ACM | 46140H | 200 | 310 | 51 | 14.3 |

| 7044ACM | 46144H | 220 | 340 | 56 | 18.5 |

| 7048ACM | 46148H | 240 | 360 | 56 | 19.7 |

| 7200AC | 46200 | 10 | 30 | 9 | 0.031 |

| 7201AC | 46201 | 12 | 32 | 10 | 0.036 |

| 7202AC | 46202 | 15 | 35 | 11 | 0.044 |

| 7203AC | 46203 | 17 | 40 | 12 | 0.08 |

| 7204AC | 46204 | 20 | 47 | 14 | 0.102 |

| 7205AC | 46205 | 25 | 52 | 15 | 0.12 |

| 7206AC | 46206 | 30 | 62 | 16 | 0.2 |

| 7207AC | 46207 | 35 | 72 | 17 | 0.3 |

| 7208AC | 46208 | 40 | 80 | 18 | 0.37 |

| 7209AC | 46209 | 45 | 85 | 19 | 0.41 |

| 7210AC | 46210 | 50 | 90 | 20 | 0.45 |

| 7210ACM | 46210H | 50 | 90 | 20 | 0.45 |

| 7211AC | 46211 | 55 | 100 | 21 | 0.6 |

| 7211ACM | 46211H | 55 | 100 | 21 | 0.6 |

| 7212AC | 46212 | 60 | 110 | 22 | 0.81 |

| 7212ACM | 46212H | 60 | 110 | 22 | 0.81 |

| 7213AC | 46213 | 65 | 120 | 23 | 1.01 |

| 7213ACM | 46213H | 65 | 120 | 23 | 1.01 |

| 7214AC | 46214 | 70 | 125 | 24 | 1.08 |

| 7214ACM | 46214H | 70 | 125 | 24 | 1.08 |

| 7215AC | 46215 | 75 | 130 | 25 | 1.23 |

| 7215ACM | 46215H | 75 | 130 | 25 | 1.23 |

| 7216AC | 46216 | 80 | 140 | 26 | 1.48 |

| 7216ACM | 46216H | 80 | 140 | 26 | 1.48 |

| 7217AC | 46217 | 85 | 150 | 28 | 1.88 |

| 7217ACM | 46217H | 85 | 150 | 28 | 1.88 |

| 7218AC | 46218 | 90 | 160 | 30 | 2.18 |

| 7218ACM | 46218H | 90 | 160 | 30 | 2.18 |

| 7219ACM | 46219H | 95 | 170 | 32 | 2.72 |

| 7220ACM | 46220H | 100 | 180 | 34 | 3.28 |

| 7221ACM | 46221H | 105 | 190 | 36 | 3.95 |

| 7222ACM | 46222H | 110 | 200 | 38 | 4.81 |

| 7224ACM | 46224H | 120 | 215 | 40 | 5.6 |

| 7226ACM | 46226H | 130 | 230 | 40 | 7.3 |

| 7228ACM | 46228H | 140 | 250 | 42 | 7.76 |

| 7230ACM | 46230H | 150 | 270 | 45 | 10.5 |

| 7232ACM | 46232H | 160 | 290 | 48 | 14.5 |

| 7234ACM | 46234H | 170 | 310 | 52 | 16.5 |

| 7236ACM | 46236H | 180 | 320 | 52 | 18.1 |

| 7238ACM | 46238H | 190 | 340 | 55 | 18.8 |

| 7240ACM | 46240H | 200 | 360 | 58 | 24 |

| 7244ACM | 46244H | 220 | 400 | 65 | 38.5 |

| 7301AC | 46301 | 12 | 37 | 12 | 0.065 |

| 7302AC | 46302 | 15 | 42 | 13 | 0.094 |

| 7303AC | 46303 | 17 | 47 | 14 | 0.12 |

| 7304AC | 46304 | 20 | 52 | 15 | 0.146 |

| 7305AC | 46305 | 25 | 62 | 17 | 0.23 |

| 7306AC | 46306 | 30 | 72 | 19 | 0.35 |

| 7307AC | 46307 | 35 | 80 | 21 | 0.47 |

| 7307ACM | 46307H | 35 | 80 | 21 | 0.47 |

| 7308AC | 46308 | 40 | 90 | 23 | 0.69 |

| 7308ACM | 46308H | 40 | 90 | 23 | 0.69 |

| 7309AC | 46309 | 45 | 100 | 25 | 0.89 |

| 7309ACM | 46309H | 45 | 100 | 25 | 0.89 |

| 7310AC | 46310 | 50 | 110 | 27 | 1.08 |

| 7310ACM | 46310H | 50 | 110 | 27 | 1.08 |

| 7311AC | 46311 | 55 | 120 | 29 | 1.39 |

| 7311ACM | 46311H | 55 | 120 | 29 | 1.39 |

| 7312AC | 46312 | 60 | 130 | 31 | 1.71 |

| 7312ACM | 46312H | 60 | 130 | 31 | 1.71 |

| 7313AC | 46313 | 65 | 140 | 33 | 2.09 |

| 7313ACM | 46313H | 65 | 140 | 33 | 2.09 |

| 7314AC | 46314 | 70 | 150 | 35 | 2.67 |

| 7314ACM | 46314H | 70 | 150 | 35 | 2.67 |

| 7315AC | 46315 | 75 | 160 | 37 | 3.1 |

| 7315ACM | 46315H | 75 | 160 | 37 | 3.1 |

| 7316AC | 46316 | 80 | 170 | 39 | 3.97 |

| 7316ACM | 46316H | 80 | 170 | 39 | 3.97 |

| 7317AC | 46317 | 85 | 180 | 41 | 4.84 |

| 7317ACM | 46317H | 85 | 180 | 41 | 4.84 |

| 7318AC | 46318 | 90 | 190 | 43 | 5 |

| 7318ACM | 46318H | 90 | 190 | 43 | 5 |

| 7319ACM | 46319H | 95 | 200 | 45 | 5.7 |

| 7320ACM | 46320H | 100 | 215 | 47 | 7.53 |

| 7321ACM | 46321H | 105 | 225 | 49 | 8.62 |

| 7322ACM | 46322H | 110 | 240 | 50 | 11.3 |

| 7324ACM | 46324H | 120 | 260 | 55 | 15.6 |

| 7326ACM | 46326H | 130 | 280 | 58 | 17.3 |

| 7328ACM | 46328H | 140 | 300 | 62 | 22.4 |

| 7328BM | 66328H | 140 | 300 | 62 | 22.4 |

| 7330ACM | 46330H | 150 | 320 | 65 | 26 |

| 7332BM | 66332H | 160 | 340 | 68 | 30.2 |

| 7334BM | 66334H | 170 | 360 | 72 | 35.6 |

| 7336BM | 66336H | 180 | 380 | 75 | 41.3 |

| 7338BM | 66338H | 190 | 400 | 78 | 45.5 |

| 7344BM | 66344H | 220 | 460 | 88 | 70 |

| 7406AC | 46406 | 30 | 90 | 23 | 0.77 |

| 7406ACM | 46406H | 30 | 90 | 23 | 0.77 |

| 7407AC | 46407 | 35 | 100 | 25 | 0.95 |

| 7407ACM | 46407H | 35 | 100 | 25 | 0.95 |

| 7408AC | 46408 | 40 | 110 | 27 | 1.41 |

| 7408ACM | 46408H | 40 | 110 | 27 | 1.41 |

| 7409ACM | 46409H | 45 | 120 | 29 | 1.77 |

| 7410ACM | 46410H | 50 | 130 | 31 | 2.1 |

| 7412ACM | 46412H | 60 | 150 | 35 | 2.8 |

| 7413ACM | 46413H | 65 | 170 | 40 | 3.85 |

| 7414ACM | 46414H | 70 | 180 | 42 | 5.9 |

| 7416ACM | 46416H | 80 | 200 | 48 | 7 |

| 7418ACM | 46418H | 90 | 225 | 54 | 10 |

thin section angular contact ball bearing 7208C Catalogue:

| Bearing | b | D | B | Cr | Cor | Weight |

| (mm) | (mm) | (mm) | (kN) | (kN) | (kg) | |

| 7208C | 40 | 80 | 18 | 36.4 | 25.2 | 0.382 |

| 7208AC | 40 | 80 | 18 | 33.6 | 23.3 | 0.382 |

| 7208B | 40 | 80 | 18 | 30.6 | 21.3 | 0.382 |

| 7209C | 45 | 85 | 19 | 40.8 | 28.7 | 0.43 |

| 7209AC | 45 | 85 | 19 | 37.7 | 26.6 | 0.43 |

| 7209B | 45 | 85 | 19 | 34.3 | 24.3 | 0.43 |

| 7210C | 50 | 90 | 20 | 42.8 | 31.8 | 0.485 |

| 7210AC | 50 | 90 | 20 | 39.4 | 41.3 | 0.485 |

| 7210B | 50 | 90 | 20 | 37.535.7 | 26.7 | 0.485 |

| 7211C | 55 | 100 | 21 | 52.9 | 40.2 | 0.635 |

| 7211AC | 55 | 100 | 21 | 48.7 | 37.1 | 0.635 |

| 7211B | 55 | 100 | 21 | 44.1 | 33.8 | 0.635 |

| 7212C | 60 | 110 | 22 | 64 | 49.5 | 0.82 |

| 7212AC | 60 | 110 | 22 | 58.9 | 45.7 | 0.82 |

| 7212B | 60 | 110 | 22 | 53.4 | 41.6 | 0.82 |

| 7213C | 65 | 120 | 23 | 73.1 | 58.7 | 1.02 |

| 7213AC | 65 | 120 | 23 | 67.3 | 54.2 | 1.02 |

| 7213B | 65 | 120 | 23 | 60.9 | 49.3 | 1.02 |

| 7214C | 70 | 125 | 24 | 75.9 | 60.2 | 1.12 |

| 7020 | 100 | 150 | 24 | 69.8 | 55.6 | 1.12 |