|

Xi'an Hongtu bearings Co.,Ltd.

|

Export manufacturer ball bearings 3307

| Payment Terms: | T/T |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

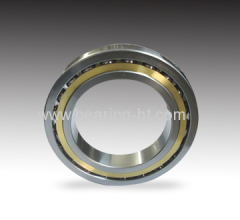

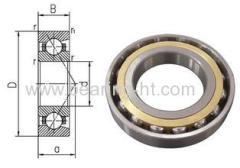

Angular Contact Ball Bearings:

1.Doubel sealed

2.Best price

3.Double row

4.High quality

5.Prompt delivery

Introduction

Angular contact ball bearing can bear radial load and axial load,and can work in high revolving speed.

Application feilds

Machine tool spindle, high frequency motor, gas turbine, centrifugal separator, small car front wheel, filling machine, differential pinion shaft, booster pump, drilling platform, food machinery, dividing head, low noise type cooling tower, electrical equipment, coating equipment, machine tool trough plate, arc welding machine.

Doubel sealed 3307 bearings & ball bearings 3307

Descriptions of 3307 bearings

An angular contact ball bearing uses axially asymmetric races. An axial load passes in a straight line through the bearing, whereas a radial load takes an oblique path that tends to want to separate the races axially. So the angle of contact on the inner race is the same as that on the outer race. Angular contact bearings better support "combined loads" (loading in both the radial and axial directions) and the contact angle of the bearing should be matched to the relative proportions of each. The larger the contact angle (typically in the range 10 to 45 degrees), the higher the axial load supported, but the lower the radial load. In high speed applications, such as turbines, jet engines, and dentistry equipment, the centrifugal forces generated by the balls changes the contact angle at the inner and outer race.

3307 Chrome Steel bearing, angular contact ball bearing, is made of Chrome Steel. which have a contact angle so that they can sustain significant axial loads in one direction together with radial loads.

The features of 3307 angular contact ball bearing is that it can bear both radial load axial load, the axial load capacity depends on how big the contact angle is, the bigger angle, the bigger capacity.

Angular Contact Ball Bearing is mainly applied on high speed, high precision and little axial load occasions, such as airplane engine main shaft, machine tool main shaft and main shafts of other high speed precision machine. It can also be applied on high frequency motor, steam turbine, oil pump, air compressor and printing machine etc. It is one of the bearings most widely used in machinery industry.

3307 double row Angular contact ball bearings with 25°contact angle. Theirrevised polyamide cages were optimised on the basis of objectives similar to those for the steel cages: higher rigidity, better grease distribution, reduced energy consumption and thus lower generation of heat and noise. This allows higher speeds as well as a longer grease and bearing operating life.

3307 bearings have raceways in the inner and outer rings that are displaced with respect to each other in the direction of the bearing axis. This means that they are designed to accommodate combined loads, i.e. simultaneously acting radial and axial loads.The axial load carrying capacity of angular contact ball bearings increases with increasing contact angle. The contact angle α is defined as the angle between the line joining the points of contact of the ball and the raceways in the radial plane, along which the load is transmitted from one raceway to another, and a line perpendicular to the bearing axis.

Quick details of 3307 bearings

| Ball Bearing Type | Angular Contact | |

| Cage Material | Fibreglass Reinforced PA 6.6 | |

| Number Of Rows | 2 | |

| Inside Diameter | 35mm | |

| Outside Diameter | 80mm | |

| Race Width | 34.9mm | |

| End Type | Open | |

| Race Type | Plain | |

| Bore Type | Parallel | |

| Static Load Rating | 35.5kN | |

| Dynamic Load Rating | 52kN | |

| Maximum Speed - Oil | 7500rpm | |

| Reference Speed | 8500rpm | |

| Limiting Speed | 8500rpm | |

| Maximum Speed - Grease | 5600rpm |

Applications of 3307 bearings

Double row 3307 angular contact ball bearing: oil pump, arjen robben, air compressor, air blower watts of all kinds of transmission, fuel injection pump, printing machine.

Advantages of 3207 bearings

1.Low friction, almost noiseless and high rolling speed

2.Easy to install

3.Simple structure ensures fast equipment

4.Optimised internal design

5.High load ratings

6.Increased limiting speed

7.High strength ball guided brass cage

8.High dimensional and running accuracy

9.Narrow axial clearances or preloads range

10.Universal facing in standard